How partners SKAN, groninger and HOF created a unified solution with integra

SKAN and groninger have been working together for years in a partnership characterised by trust, dependability and a passion for innovation. The complementary expertise of the two companies – SKAN in isolators and groninger in filling systems – makes them perfect partners. The recent ‘Fast Skin’ project for Merz Pharma in Dessau, Germany demonstrated how collaboration between SKAN and groninger can produce unified solutions. This project involved a high-output line with an integrated isolator and two freeze dryers, which is used to process vials in bulk.

About Merz Pharma

Merz Pharma GmbH & Co. KGaA is an ‘old hand’ in the industry, successfully marketing pharmaceutical and consumer care products as a family business since 1908. The pharma business is divided into Merz Aesthetics and Merz Therapeutics. The company’s product portfolio includes innovative pharmaceuticals and medical products for cosmetic applications and neurology.

At the future location Biopharmapark Dessau-Roßlau, Merz is currently greatly expanding its production capacity in the areas of Merz Aesthetics and Merz Therapeutics. The products manufactured here are based on the active ingredient botulinum neurotoxin, which is primarily used in cosmetic procedures but is also used to treat neurological conditions.

Mission: treble capacity

In brief, the mission of the joint project was to treble production capacity for Merz Pharma in Dessau using just one new system and in the shortest possible time. A new purpose-built production hall was constructed, doubling the production area at the site. Completing a project of this scope successfully – and above all quickly – called for expert partners.

So, in the last quarter of 2020, the joint project was initiated under the name Fast Skin. The core of the line is a modular filling solution combined with an integrated SKAN isolator. This successful concept has already been proving itself on the market under the name integra for some years. The line is completed by two freeze dryers from HOF.

To allow production to start quickly, keeping the delivery time to a minimum was crucial to the project. Due to the increasing demand, the capacity expansion was absolutely necessary therefore the company decided to think big.

The integra machine concept

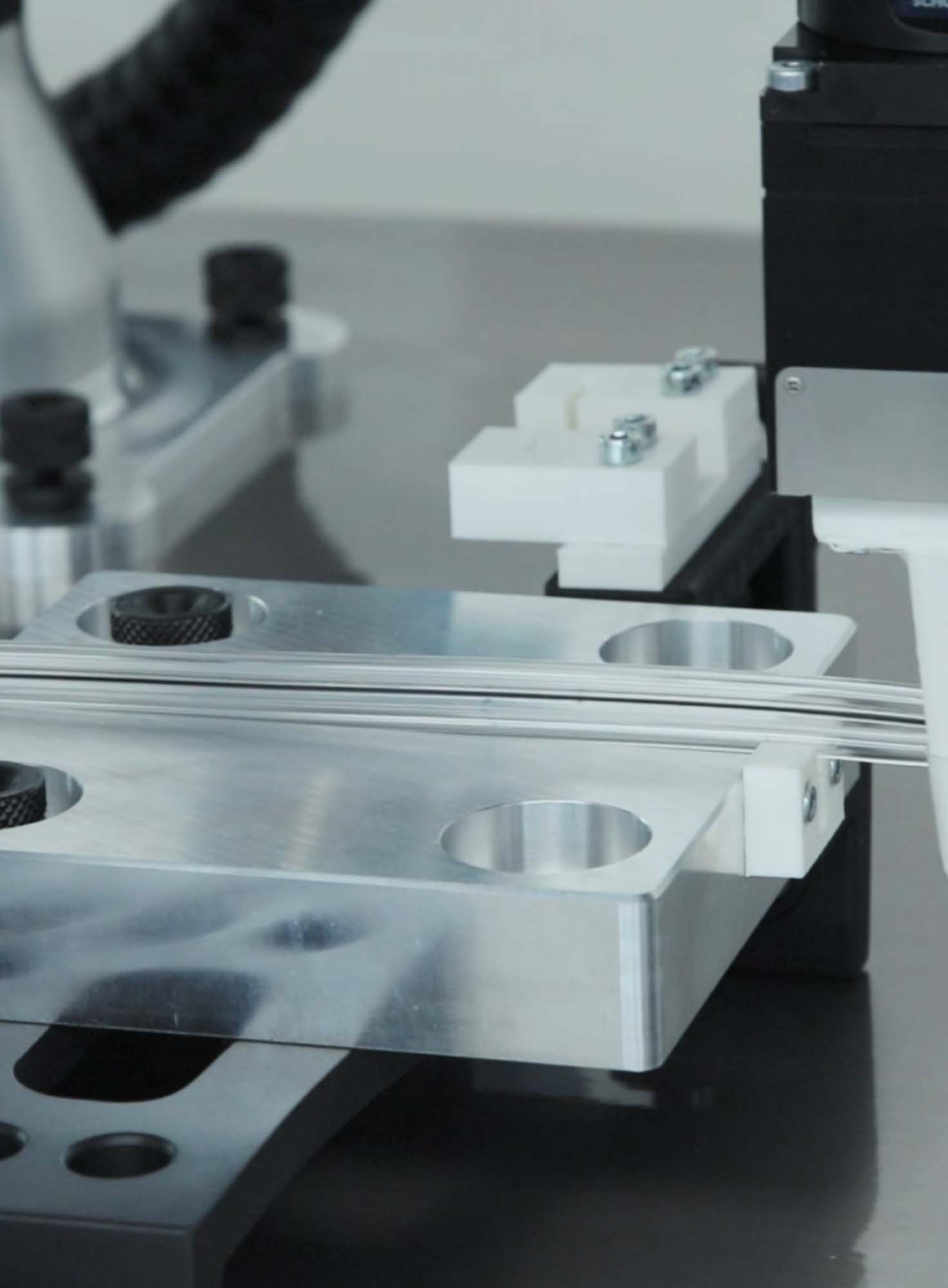

As the name implies, integra stands for optimum integration – particularly in isolator lines. Together with groninger, industry experts in filling lines, SKAN has developed a unique, advanced machine concept that draws on the expertise of both companies.

Combining a modular high-tech filling system with a state-of-the-art isolator, it’s not surprising that in 2018 the integra concept won the ACHEMA Innovation Award. The solid partnership between SKAN and groninger benefits customers twice over, because not only is the product optimally integrated and supplied from a single source, but project handling also becomes much simpler.

The project

Merz Pharma, too, was impressed by the integra concept, leading to the joint project being launched in the autumn of 2020. The third partner involved in the collaboration was HOF Sonderanlagenbau, which contributed its expertise as a specialist in freeze dryers.

The equipment had to fulfil stringent criteria: a user-friendly machine with three times the production capacity of the existing system. Another challenge was installing the machine during Merz Pharma’s ongoing production process. In March 2022 the line was installed in the designated hall at Merz Pharma, marking the successful accomplishment of this joint undertaking. It proved that when all partners work together with a shared vision, there is no limit to what can be achieved.

Partnership is key

Throughout the project, a strong partnership developed between the participating companies. Thanks partly to the integra concept, the process of coordinating the mock-up stage, construction and so on went without a hitch.

Generally, the project demonstrated to everyone involved the importance of a strong partnership and mutual trust. Given the long-standing business relationship, there was already a good mutual understanding of the processes involved, which allowed the partners to communicate easily and openly. The solution-oriented approach of all partners helped this mega-project to be implemented within the desired time frame, even in spite of the pandemic.

The result was the installation of a smart, efficient and digitised machine at Merz Pharma.