The demand for automation in laboratories is steadily increasing. However, the requirements for a robot-assisted application in this context are high. The Fraunhofer IPA demonstrates how to implement this technically and economically sensibly with the help of a prototype in collaboration with SKAN.

Robots automate sterility tests in laboratories

Handling objects has always been one of the tasks that robots frequently perform. For many application cases, this has already been optimally solved and used in mass production for years. An example being the vehicle body of automobiles being lifted by machines in the body shop. However, in many other environments, there is a strong demand for more automation with robotics. This includes laboratories in the life science and pharmaceutical industry.

In laboratory environments, there are numerous non-ergonomic, repetitive, and accordingly monotonous tasks that are less appealing to skilled workers. Additionally, laboratory operators must first find qualified laboratory professionals in times of labor shortages. Robotics can help relieve available professionals, allowing them to use their capacities for more value-added activities. Furthermore, efficient, repeatable, and process-secure work, as well as seamless and error-free documentation, are essential in the laboratory, for which robotics is also well-suited. If the robotic solution is designed to be modular, it can meet the flexible requirements in this complex environment.

Robots handle hoses

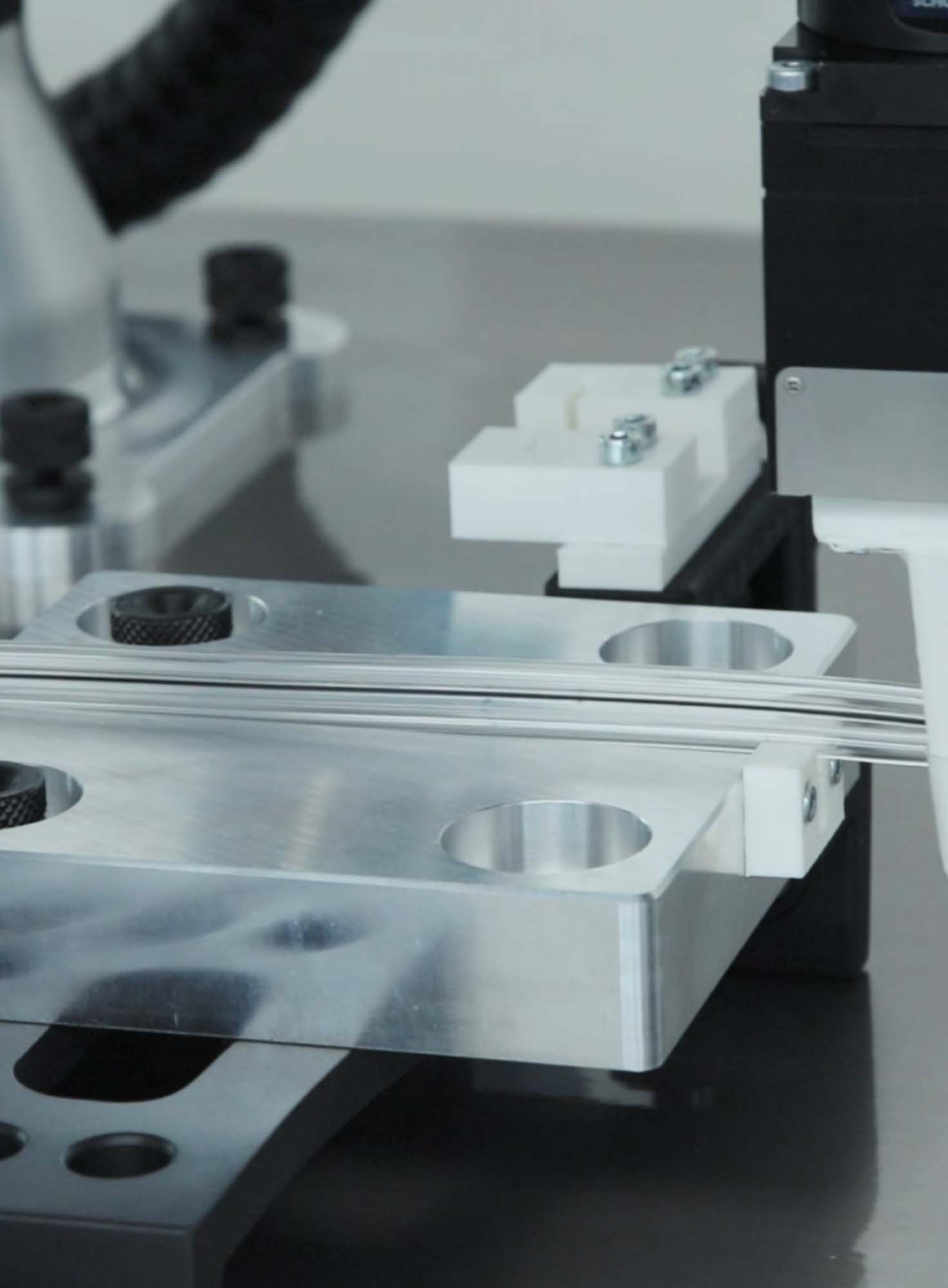

An exemplary development for the automated handling of sterility tests as part of quality control in pharmaceutical production has emerged from two projects at the Fraunhofer IPA in collaboration with SKAN. While the first collaboration focused on examining the basic feasibility, the next step resulted in a prototypical handling solution that has already been registered for a patent. In this process, two industrial robots, whose movements are semi-synchronized, pick sterility tests from the packaging, identify and grasp a hose, and place it in a peristaltic pump. The robot cell corresponds to the dimensions of a typical sterilizer at SKAN.

One challenge is that the hoses are flexible and therefore not easy to handle. Additionally, there is a risk of them getting tangled. However, in a feasibility study, the development team demonstrated that the prototype operates robustly and process-reliable.

In general, robot-based applications for laboratories need to be adapted to the requirements of this operating environment. The mentioned flexible parts such as hoses or bags and the like are typical objects that a robot must be able to handle through appropriate trajectory planning and gripping technology. Furthermore, specifications regarding sterility or cleaning processes in the production environment, such as those set by, for example, Good Manufacturing Practice (GMP), are strict. Finally, the laboratory and pharmaceutical environment, in general, are highly regulated, requiring the processes and systems deployed to operate with high reliability.

Expertise in automation and laboratory processes

The development of the application incorporates extensive knowledge of challenging assembly, disassembly, and handling solutions, as well as around 50 years of experience with feasibility studies related to automation. These studies range from conception through customer-specific tool and fixture construction, the setup and evaluation of robot applications to the transition to small-scale production. For the collaboration with SKAN, experts from the specialized departments of robot and assistance systems, laboratory automation and bioproduction technology worked together in an interdisciplinary manner at Fraunhofer IPA, allowing them to contribute the relevant industry knowledge to the application development.

SKAN is currently planning to further develop the prototype into a series product with the help of a system integrator or plant manufacturer. The Fraunhofer IPA can provide further extensive support with this technology transfer.

This article has already appeared in German on “interaktiv,” the news platform of Fraunhofer IPA, under the following title: Roboter automatisieren Sterilitätstests in Labors

About Fraunhofer IPA

With nearly 1 200 employees, the Fraunhofer Institute for Manufacturing Engineering and Automation, Fraunhofer IPA, is one of the largest institutes in the Fraunhofer-Gesellschaft. The total budget amounts to € 90 million. The institute’s research focus is on organizational and technological aspects of production. We develop, test and implement not only components, devices and methods, but also entire machines and manufacturing plants. Our 19 departments are coordinated via six business units, which together conduct interdisciplinary work with the following industries: automotive, machinery and equipment industry, electronics and microsystems, energy, medical engineering and biotechnology as well as process industry. The research activities of Fraunhofer IPA aim at the economic production of sustainable and personalized products.