Requirements

- Personal and environmental protection against chemicals, solvent vapours and active substances

- Low extract airflow, limited building duct capacity

- Energy-saving and resource-saving

- Nothing deposited in the outgoing airflow ducts

Tested

Designed and tested to SN EN 14175-3 Focus on the future

Focus on the future

E-loop

Resource-saving partial recirculation principle

Special filter technology

The ‘e’ in e-loop stands equally for economic (economical) and ecological (ecological).

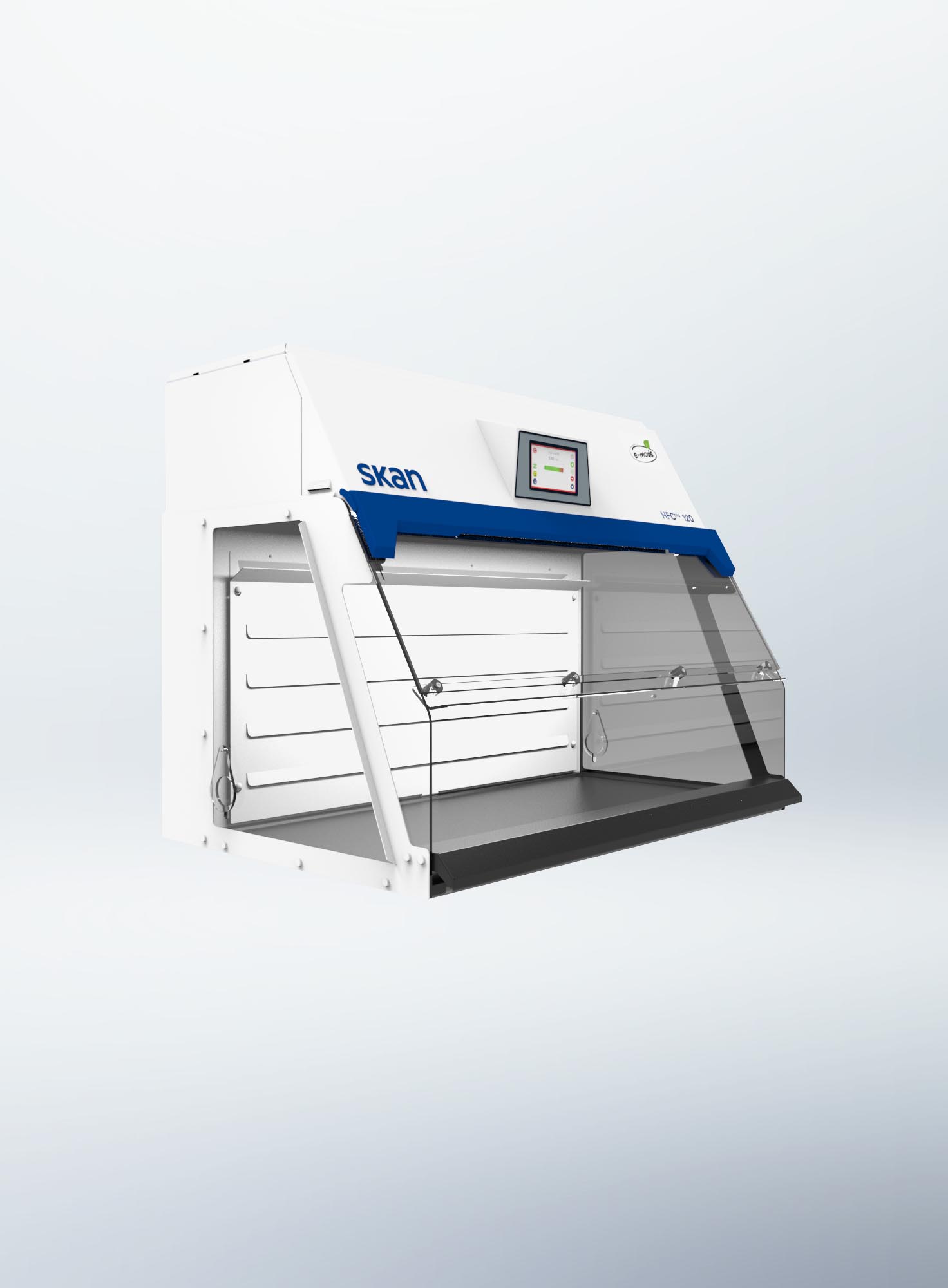

The SKAN development combines all technical measures for the cost-saving and resource-conserving partial air circulation principle of the Workstation evo. When working, you will not notice any difference in terms of safety and ergonomics compared to conventional fume cupboards. The main differences lie in the unique air routing and the special filter technology. Compared to conventional fume cupboards, the amount of exhaust air and the energy used is reduced many times over.

This extends building utilisation, saves costs and is sustainable.

In addition, less supply and exhaust air needs to be treated in the room, which saves enormous operating costs over long periods of time and conserves resources.

Downloads

Technical specification

| Technical Data (in mm) | Workstationevo 120 | Workstationevo 150 | Workstationevo 180 |

|---|---|---|---|

| Outer dimensions (W x D* x H**) *without fittings **with outgoing air nozzle, +172 mm with open front glass | 1203 x 945 x 2563 | 1503 x 945 x 2563 | 1803 x 945 x 2563 |

| Dimensions work zone (W x D x H) | 1137 x 592 x 1312 | 1432 x 592 x 1322 | 1732 x 592 x 1322 |

| Total air volume | 419 m3/h +/- 5 % | 528 m3/h +/- 5 % | 598 m3/h +/- 5 % |

| Outgoing air volume | 230 m3/h +/- 5 % | 240 m3/h +/- 5 % | 260 m3/h +/- 5 % |

| Recirculation air volume | 189 m3/h +/- 5 % | 288 m3/h +/- 5 % | 338 m3/h +/- 5 % |

| *The air volumes are to be understood as guide values. In reality, these values are strongly influenced by the environment and the room. |