Computational fluid dynamics (CFD) has become indispensable for solving modern flow dynamics problems. The scope of analytical solutions to the fundamental equations of fluid mechanics is limited, and when complex geometries are encountered, experts must rely on numerical methods.

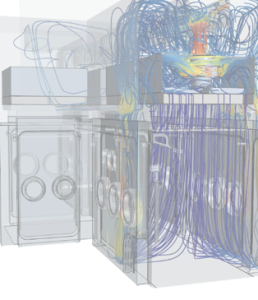

CFD provides a reliable and quick tool, generating key insights to maximize process safety. To ensure the safety of Grade A/B facilities, regular monitoring and risk assessment are necessary. Also, by following Annex 1; 9.4 guidance as a powerful indication for regular monitoring and risk assessment in Grade A/B, we rely on CFD to visualize air circulation.

While our preferred model is validated, we ensure the alignment between prediction and reality. Our advanced CFD:

- Enables simulation under real conditions in production environments

- Allows for qualitative investigation of the working space with regard to unidirectional air flow using a combination with a smoke study

- Considers and safeguards the “first air principle”

- Provides detailed simulation reports beyond the usual flow vectors

- Supports risk assessments, answering questions regarding biomonitoring, decontamination efficacy, and sources of contaminations

- Offers continuous monitoring for environmental monitoring