Integrated and Robotic Processes

Customized production tools for the future of isolator technology

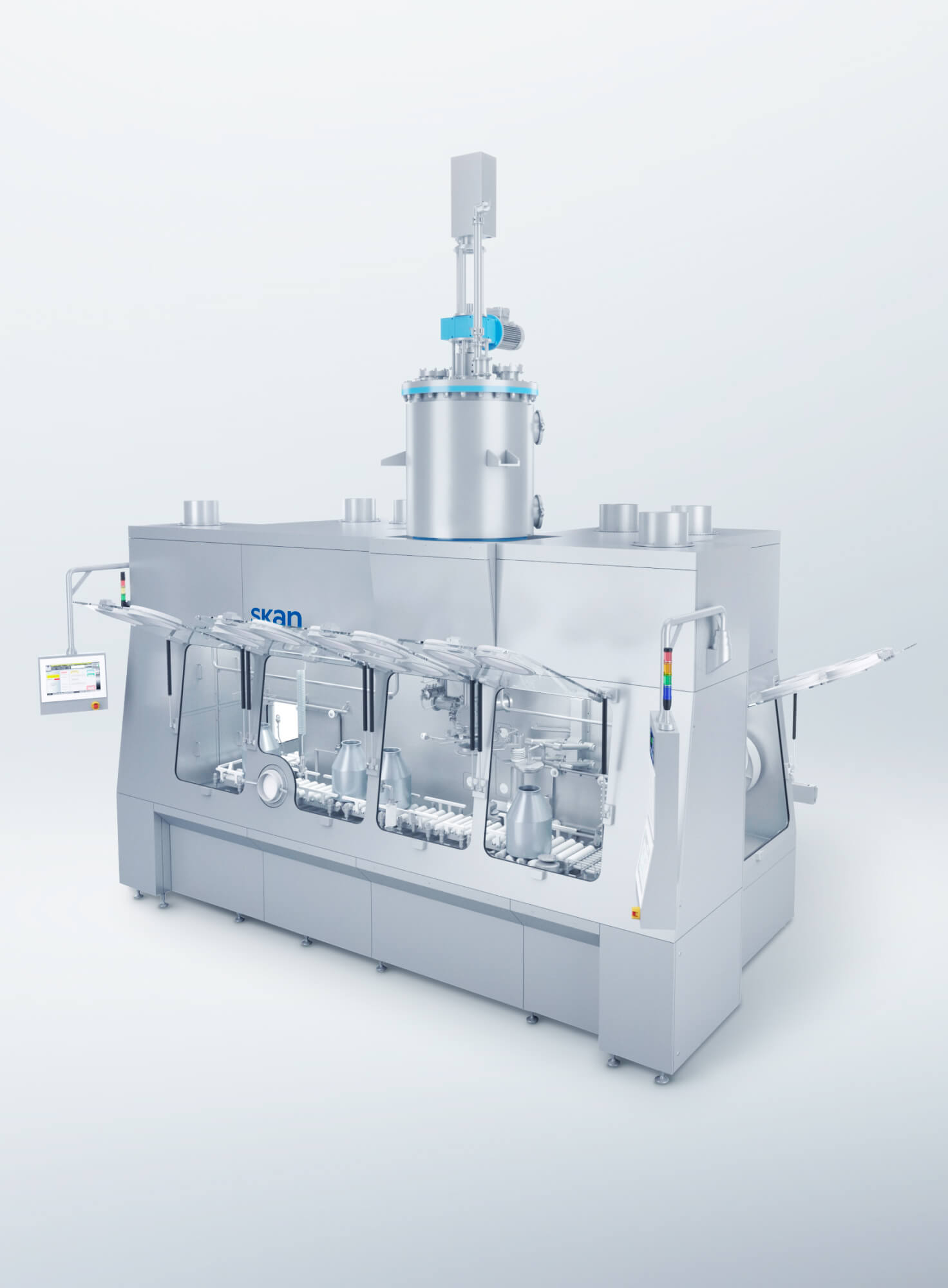

In today’s pharmaceutical industry, robotic systems and automated processes are becoming increasingly important. Because these aspects mean reliably, consistent quality, as well as enormous safety for the process and the operator, the use and integration of SKANs isolator technology for aseptic processes is inevitable.

As market leader, SKANs concern is not only to provide the most innovative technology for isolators, cleanrooms and aseptic processes, but also to think about the future challenges of customers. We are always one step ahead.

Realize your own optimized process thanks to the latest automation technology. Reduce manual intervention to a minimum. Learn more.

Your advantages of customized integrated processes

- Upgrade your production process to a new, modern level and integrate them easily into your filling lines.

- Realize your own optimized process thanks to the latest automation technology.

- Reduce manual intervention to a minimum and increase operator safety to a maximum.

- Increase the efficiency of your automated processes with the most innovative robotic technology.

- Ensure aseptic conditions with efficient and automated H2O2 decontamination.

- Obtain cGMP approval from your authorities quickly thanks to proven technology.

- Integrated processes can handle any aseptic task

Special aseptic processes that are either too complicated or too difficult are increasingly being taken over by robotic systems, which can easily be installed in isolators and filling lines. Additional automated processes, such as the neutralization of hydrogen peroxide (H2O2) within cleanrooms by integrated nanox® catalyst, guarantee maximum process efficiency and increase product and operator safety.

A large control panel facilitates the handling of the isolator and permanently provides the necessary information about the ongoing aseptic process. This data is reliably documented and stored. - Always the right solution for your process technology

Our special process team focuses on providing the right automated solution to integrate with your aseptic processes, isolator systems or filling lines.

With our expertise in H2O2 decontamination and automated robotic systems, we always find the safest and most efficient technology for your individual aseptic process to fit your working environment. The earlier we are involved in your project, the faster you can set up an efficient aseptic process. - The unique features of SKANs integrated processes

- The processes are set up and accompanied by highly qualified and experienced development engineers.

- Innovative tools for analytical validation of individual designs.

- Compatible docking systems and connected quick-change locks for your isolator system.

- Efficient collaboration with the market leader for robotics and automated solutions in isolator systems and filling lines.

- SKANs innovative solution for aseptic powder transfer enables the movement and handling of large or heavy powder cans.

- Appropriate and proven ‘Track & Trace’ solutions for your process efficiency.

- Integrated processes for aseptic process conditions

The process components used in the isolator are almost unlimited. The trend is clearly towards robot-based, automated systems to avoid operator intervention and increase safety for both the process and the operator.

Especially when processing heavy containers, robots are indispensable.

Together with its partners, SKAN has implemented various robotic systems under aseptic conditions:- Handling of containers or powder cans

- Powder processing, filling or emptying

- Dispensing or dosing

- Creation and processing of cell culture

- Realization of special liquid processes

The isolator can be used for pure product protection as well as for aseptic-toxic purposes.

- Automation

SKANs automated solutions are development according to current GAMP and fulfil all regulatory requirements.

- GMP guidelines, CFR 21 Part 11, EndraLex Volume 4

- Supervisory Control And Data Acquisition (SCADA)

- PLC Siemens or Allen Bradley

- HMI Beckhoff Industrial PC

- Beckhoff touchscreen monitor

- Active Directory

- Decontamination report

- Batch report

- Campagne report

- Audit trail functionalities

- Electronic records

- Electronic signature

- OPC interface

- Options and accessories

- Rapid transfer material airlock SARA

- Rapid transfer port for solids (RTP)

- Rapid transfer port for liquids (AT -Port™)

- H2O2 TLV sensor for room monitoring (operator safety)

- H2O2 LC sensor (low concentration) for isolator chamber

- H2O2 HC sensor (high concentration) for isolator chamber

- Viable monitoring according to your choice

- Particle counter (non-viable) according to your choice

- Glove testing devices with position control function

- Negative pressure operation mode for special application

- Robot and conveyor system for heavy powder cans

Get in touch with our sales team!

Recommendations

Related services

Isolator Support

Requalifications, corrective maintenance and recalibrations

Isolator Support

Requalifications, corrective maintenance and recalibrations

SKAN offers professional support to ensure that your equipment is operating at maximum productivity and reliability. The development of comprehensive maintenance programs and services covering all aspects of SKAN equipment was inspired by the decades of hands-on experience of SKANs experts.

Our certified technicians perform precise recalibrations and repairs as well as modification requests on site, to maintain the qualified status of your equipment. Also microbiological recalibrations to check the effectiveness of the decontamination process and to guarantee the safety of the workplace, can be realized professionally and reliably.

Interested in learning more?

Support Hotline

Solving yours issues and supporting your operations

Support Hotline

Solving your issues and supporting your operations

Besides the isolator support, SKAN completes its comprehensive LifeCycle Support portfolio with a 24-hour emergency service hotline. Our service hotline is staffed by a dedicated team of specialists who provide direct and efficient support for all types of troubleshooting.

Interested in learning more?

Spare Parts and Obsolete Management

Your one stop spare part provider

Spare Parts and Obsolete Management

Your one-stop spare part provider

Optimal operation of an isolator can only be guaranteed if every part functions reliably. Even minimal malfunctions as well as the unavoidable wear of parts in an isolator can lead to long downtimes. Therefore, it is important to be able to rely on the right partner, with worldwide spare parts warehouses and well-planned stock levels.

SKAN offers a comprehensive spare parts service as well as reliable obsolescence analysis, through which you benefit from active risk minimization and a flawless production.

Have we aroused your interest?

Engineering

Innovative and creative engineering for optimal solutions

Engineering

Innovative and creative engineering for optimal solutions

Thanks to state-of-the-art equipment and in-depth expertise, SKAN Stein AG is the right partner to perform tests and simulations of your machines and processes. In addition to strength calculations (FEM) of containers and pedestals and calculations of air flows (CFD), the experienced engineering team also takes care of the design and implementation of individually designed tests. Our experienced technicians are able to carry out various tests and simulations remotely at SKANs facilities. With SKAN Stein AG, you can count on the best possible all-round support for your project.

SKAN Stein Services

Realistic Mockup Studies

Pre-design of individual isolators and plants with SKANs mockups

Realistic Mockup Studies

Pre-design of individual isolators and plants with SKAN Mockups

Isolator systems and integrated technology are becoming increasingly complex. Individual plants and isolators often combine a variety of process systems from different manufacturers. Due to the integration of different systems, even the smallest detail can be crucial to the successful operation and validation of the entire system.

SKAN offers its customers the possibility of realistic mockup studies. These studies have a significant impact on the design phase of an isolator process by pre-designing the entire system according to reality conditions in a model. The mockups are always developed in close cooperation between SKAN, the customer and the supplier to meet the individual requirements.

Design individual previews with SKAN Mockups:

- The special CAM cardboard system enables dimensionally accurate production

- The cardboard system enables simple and quick design adjustments

- The three-dimensional structure conveys a realistic feeling and supports a more precise idea of the implementation

- The glove openings are easily adjustable on all sides

- Thanks to 3D printing, complete components can also be displayed

Interested in learning more?

Computational Fluid Dynamics Simulation

CFD – The latest method for flow simulation of liquids and gases

Computational Fluid Dynamics Simulation

CFD – The latest method for flow simulation of liquids and gases

Understanding and controlling airflow in aseptic isolators is crucial for ensuring a sterile environment, but it’s often complex due to various factors affecting the flow dynamics.

Computational Fluid Dynamics (CFD), a specialized area within fluid mechanics, uses numerical algorithms to model and simulate fluid flows. Employing CFD allows for a detailed analysis of airflow patterns inside isolators, eliminating the need for costly and time-consuming experiments like smoke studies.

At SKAN, we offer CFD services designed to address your engineering requirements with precision and efficiency.

- High-fidelity simulations employing state-of-the-art techniques for predicting airflow patterns in isolators

- Rigorous risk assessment analysis for contamination using detailed particle tracking

- Comprehensive reports with visualizations to facilitate decision-making and reduce design risks

- Performing sensitivity analysis on desired parameters across critical sections

- Utilizing nearly real-time airflow simulation to optimize designs by exploring various geometries within isolator or filling line sections

Our CFD services include:

Employ the expertise of SKAN’s CFD services to optimize your processes and minimize risks through advanced CFD analysis.

Interested in learning more?

SKANalytix

Analytical services provided by SKAN analytics experts

SKANalytix

Analytical services provided by SKAN analytics experts

In addition to the successful operation of isolators and plants, SKAN also supports its customers with SKANalytix in the area of data analysis, data evaluation and documentation. To meet the different requirements SKAN offers the analytical service packages active, clean and persist.

The services include the analysis of the cleanability of isolators, the evaluation and development of individual cleaning processes, the determination of suitable packaging materials and the H2O2 influence on sterility tests.

It goes without saying that we follow the standards of “Good Manufacturing Practice” (GMP) as well as common standards and guidelines both in the execution and documentation of services.