Safety cabinets for the production of cytostatics and parenteral nutrition

As a leading centre of competence in hospital pharmacology, Kantonsapotheke Zürich provides a wide range of services with a high standard of quality and cost-efficiency.

In 2019, Kantonsapotheke Zürich received ISPE’s coveted Facility of the Year Award.

Application

- Cytostatics

Cytostatics inhibit cell growth and multiplication. In a healthy person, this is not desirable or beneficial. But in patients with tumour cell growth, cytostatics are the most promising chance of a cure as part of a treatment programme. Both users and products require special protection.

- Parenteral nutrition

Parenteral nutrition involves giving a patient – usually an infant or premature baby – fluids and nutrients direct into the bloodstream by infusion. This requires an absolutely clean environment.

Our solution

- Cytostatics

Like many other hospital pharmacies and oncology departments, Kantonsapotheke Zürich relies on the Berner Claire® safety cabinet. This provides a class A work zone in GMP class B cleanrooms. The Claire® safety cabinet offers maximum protection and is ideal for the production of cytostatics.

Claire® safety cabinets are future-proof, far exceeding the minimum level of protection currently required for the preparation of CMR drugs.

The safety cabinets at Kantonsapotheke Zürich were equipped with additional monitoring instruments at the customer’s request. As well as the standard air velocity indicator on the display, a measurement probe for laminar air flow was installed. The number of particles inside the cabinet is also continuously monitored. Both values (air velocity and particle count) are communicated to the building’s control system in real time. If they exceed the specified tolerances, the user is alerted by a warning light on the ceiling.

- Parenteral nutrition

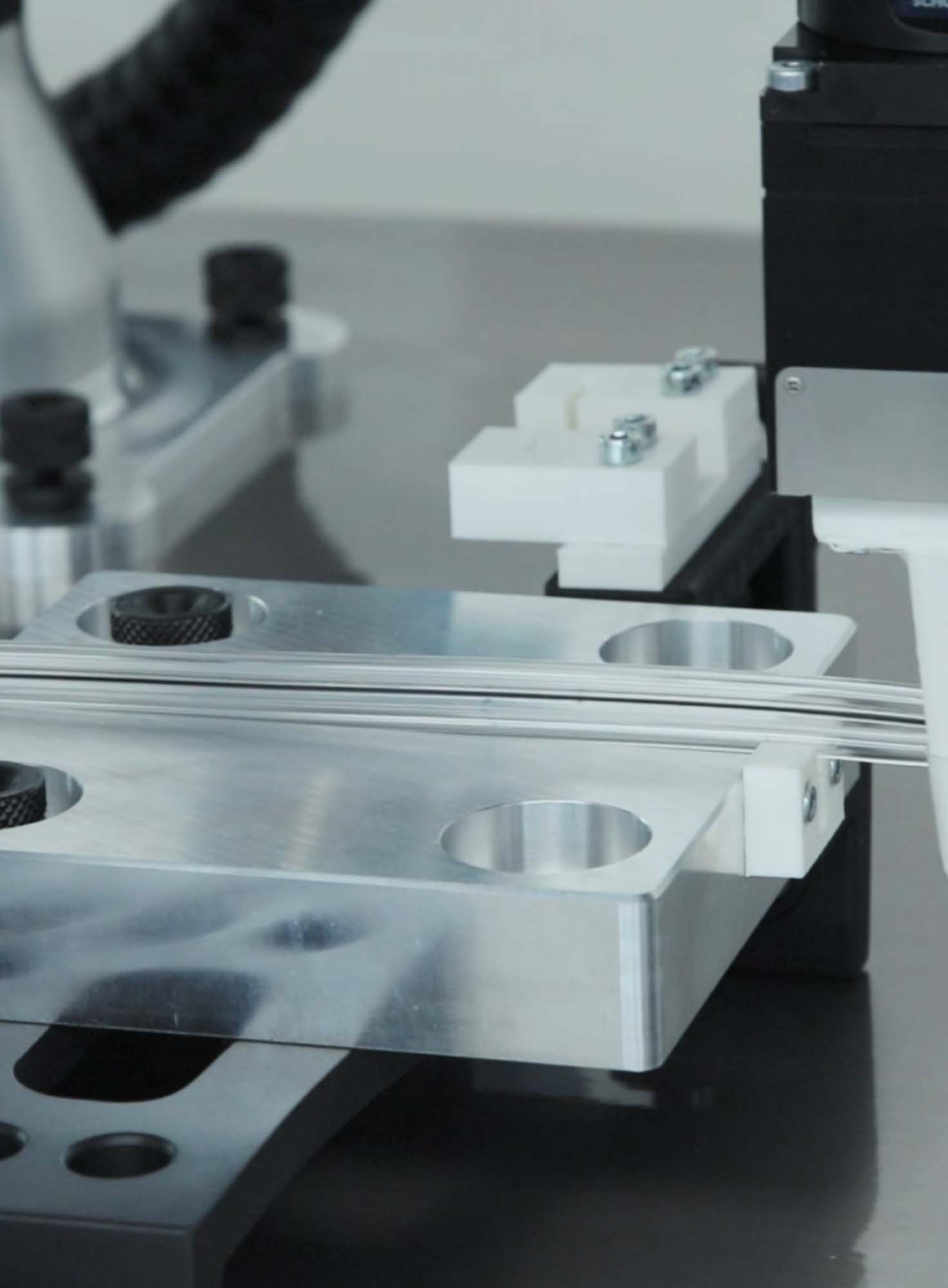

Mixtures of electrolytes, carbohydrates, amino acids, vitamins and trace elements are transferred into infusion bags with the aid of a compounder pump inside two SKAN laminar flow systems.

These interconnected laminar flow systems protect the product and ensure a clean, particle-free environment (GMP A). Both SKAN systems were customised to the pharmacy’s individual requirements. Screen interfaces and scales for the formulation were integrated and measurement probes for monitoring airborne particles and air velocity were added.